Updated: August 2023

It’s a question we get asked from time to time: which roof coating performs best? The short and simple answer is—it depends. That’s because there are just too many variables to consider regarding the performance, longevity, and suitability of an elastomeric roof coating.

Below, we provide a comprehensive overview of the benefits, chemistry types, and physical properties to look for in an effective coating solution.

Table of Contents

Attention! Are you interested in coating your roof? Click here to schedule your free roof inspection with an American WeatherStar Approved Contractor.

The Benefits of Roof Coatings

Elastomeric roof coatings have been around for a long time. That being said, many facility owners and managers are still relatively unaware of the numerous advantages they provide.

Before we get into the strengths and weaknesses of the various types of coating chemistries available in the industry, let’s get an idea of the many benefits a coating system provides, in general.

Costs Less

Roof replacement can be quite expensive. Depending on the type of roof you have, a full replacement can cost anywhere from $5 to $15 per sq. ft.

A roof coating system (or roof restoration system), on the other hand, provides all the benefits of a new roof but for a fraction of the cost.

Roof coatings are applied directly to existing roof surfaces. As such, they carry a fraction of the labor and material costs associated with a traditional roof tear-off and replacement. This means you can expect to pay 50-70% less with the installation of a roof coating system.

Extends Life

Perhaps the best-known quality of an elastomeric coating system is its ability to extend roof life. The average commercial roof only lasts about 20 years, but the addition of a coating system can prolong a roof’s serviceable life by up to 10, 15, or even 20 years.

If properly installed and maintained, a coating system has the potential to be recoated numerous times.

It also can significantly reduce the need for constant maintenance and repair.

Reduces Energy Costs

Coating your roof is a great way to improve the energy efficiency of your building.

Unlike conventional dark-colored roofing materials, white roof coatings can reflect 80-90% of the sun’s harsh UV rays and diminish the flow of heat to your building. This reduces the workloads of HVAC systems during warm summer months and cuts interior cooling costs by up to 20% on average.

Additionally, the superior reflective and emissive qualities of a coating system can significantly cool roof surface temperatures (pictured above) and provide a more comfortable work environment for building occupants.

Unconditioned spaces can experience a reduction in ambient temperatures, as well.

Improves Sustainability

In recent years, the demand for more sustainable roofing solutions has grown considerably due to more stringent environmental regulations and building codes as well as increased concern for the environment.

Commercial roof tear-offs contribute millions of tons of waste to landfills each year.

In contrast, there is no tear-off required prior to the application of a commercial roof coating system, allowing you to reuse existing roofing materials with minimal impact on the environment.

As mentioned above, the prospect of recoating also contributes to increased sustainability.

Environmentally Friendly

In addition to improved sustainability efforts, many of today’s elastomeric coatings are developed with little to no VOCs (volatile organic compounds), making them much safer for the environment.

This also means buildings with a roof restoration system could qualify for the US Green Building Council’s LEED program.

Common Types of Roof Coating

Choosing the best coating for a particular roofing environment depends on a variety of factors such as roof type, age, weather conditions, environmental concerns, aesthetics, etc. Below, we take an in-depth look at some of the key strengths and weaknesses of today’s most common types of coating.

Acrylic

Acrylic roof coatings are among the most durable and inexpensive elastomeric coatings in the industry. Comprised of high solids emulsion polymers and potent biocides, these highly reflective coatings are ideally suited for extreme UV climates and provide superior resistance to mildew and dirt accumulation.

Acrylic coatings are often used to restore aged metal roofs, but they also work on a number of different roofing substrates such as modified bitumen, single-ply, built-up roofs, and spray polyurethane foam.

Acrylics are easy to work with and come in a variety of different standard, premium, and custom colors. These materials can be spray or roll-applied at a rate of .75 to 1.5 gallons per 100 square feet, depending on the substrate.

Acrylics do not stand up well to ponding water and are only recommended for roofs with positive drainage. Cold temperature applications can also be a problem.

Because acrylic is a water-based substance, temperatures at or below 50°F can negatively affect adhesion to the roof substrate and impede cure time.

Asphalt Emulsion

Another widely used roof restoration material is asphalt emulsion. This product consists of asphalt particles dispersed in water with clay used as a bonding element.

Generally black or brown in color, asphalt emulsion contains organic and inorganic compounds, as well as other fillers to add strength and durability.

Asphalt emulsion is inexpensive and easy to work with. It is typically used to level “alligatoring” and other irregularities that commonly occur on modified bitumen and built-up roof surfaces.

Although it can be installed as a standalone roofing material, asphalt emulsion is commonly used to provide a monolithic foundation membrane for other elastomeric roof coating systems that offer better reflectivity and UV stability.

Asphalt emulsion usually requires 3 to 4 gallons per 100 square feet depending on the substrate. Multiple passes may be required to achieve proper results.

Asphalt emulsions are a water-based product, which makes them susceptible to freezing temperatures. They can also be very difficult to work with during cold weather conditions.

Butyl Rubber

Butyl coatings are a solvent-based polymer best known for their exceptional elongation and tensile strength. They are highly reflective, fast-drying, and great for roof maintenance and repair.

Due to their low permeability, butyl rubber coatings are most commonly used as a vapor-retardant barrier over spray polyurethane foam systems in cold storage/freezer applications.

A butyl coating system is suitable for a variety of commercial roof surfaces including metal, modified bitumen, single-ply, built-up roofs, and spray polyurethane foam.

They are typically white, gray, or tan in color and can be sprayed or roll-applied at a rate of about 2 gallons per 100 square feet.

The primary disadvantage of butyl coating is its low solids content. This means it takes more liquid material to achieve a certain dry mil thickness, which makes it less cost-effective than alternative coating types.

They can also be challenging to work with and lack color stability.

Silicone

Silicone roof coatings are the preferred choice when it comes to UV protection and resistance to ponding water. They erode much slower than other coatings without becoming brittle or hard. Modern silicone formulations have a high-solids content that typically exceeds 90 percent. This means less material is needed to achieve the required dry film thickness.

Silicone coatings are created by adding solvents and a catalyst to a silicone base. Available in white, gray, or tan, silicone can be installed on a variety of roof types including metal, modified bitumen, single-ply, EPDM, built-up roofs, and spray polyurethane foam. Depending on the substrate, most silicone roofing systems require multiple coats at 1.5 gallons per 100 square feet.

Silicones attract dirt rather easily. This means the system will gradually lose reflectivity over time if not cleaned periodically. They are also extremely slippery when moisture is present. Resistance to tearing is another inherent weakness. If pedestrian traffic is expected on the roof, we highly recommend incorporating roofing granules into the system.

VIDEO: Click here to learn some helpful best practices for working with silicone.

Urethane (Polyurethane)

When it comes to strength, durability, and adhesion, urethane roof coatings are second to none. Compared to other coatings, they are more impact-resistant and are better suited to handle pedestrian traffic. They are also strong enough to endure the natural expansion and contraction (thermal movement) of roof structures and the negative effects of ponding water.

There are two main types of urethane coatings: aliphatic and aromatic. Aliphatics are generally used as top coat, as they are more UV stable, resistant to dirt pick-up, and have superior color retention. Aromatics are less expensive but not quite as UV stable. They are primarily used as a foundation coating in most roof restoration systems. Both types can be spray or roll-applied, with most system specifications requiring multiple coats at a rate of 1.5 gallons per 100 square feet.

Being a xylene-based material, urethane coatings can be challenging to spray, harsh on installation equipment, and highly odorous. It’s also worth mentioning that urethanes are a moisture-cure coating, meaning they are constantly curing—even in the pail.

Warranty Considerations with Roof Coatings

When investing in a roof coating system, understanding the warranty offered by the manufacturer is crucial. Warranties assure the coating’s quality, performance, and longevity. Here are some key factors to consider when evaluating warranty options:

Coverage

Review the warranty coverage in detail. Understand what aspects of the coating system are covered, such as adhesion, reflectivity, durability, and resistance to weathering. Some warranties may also cover the cost of labor and materials in case of product failure. Ensure that the warranty covers the specific needs and requirements of your roof.

Warranty Period

The length of the warranty period is an important consideration. Longer warranty periods generally indicate the manufacturer’s confidence in the coating system’s durability and performance. However, it’s important to note that warranty length alone does not guarantee the longevity of the coating. Evaluate the warranty period with other factors, such as the coating’s physical properties and expected service life.

Maintenance Requirements

Many warranties have specific maintenance requirements that must be followed to keep the warranty valid. These requirements often include regular inspections, cleaning, and maintenance of the coating system. Failure to adhere to these requirements may void the warranty. Carefully review and understand the maintenance obligations outlined in the warranty documentation.

Recoating Intervals

Some warranties specify recoating intervals or recommend regular maintenance coatings to ensure the system’s long-term performance. These recoating intervals may vary depending on climate, roof type, and coating chemistry. Consider the recoating requirements and associated costs when evaluating the overall value of the warranty.

Manufacturer’s Reputation

Consider the reputation and credibility of the manufacturer offering the warranty. Research the manufacturer’s history, experience, and track record in the roofing industry. A reputable manufacturer with a strong track record is more likely to honor warranty claims and provide reliable customer support if issues arise.

Limitations and Exclusions

Carefully review any limitations and exclusions mentioned in the warranty. These may include specific weather conditions, improper installation, or application on certain roof types. Understanding these limitations will help you avoid actions that could void the warranty.

Warranty Transferability

Sometimes, a warranty may be transferable to a new owner if the property is sold. This can be an attractive feature when considering the long-term value of the coating system. Check whether the warranty is transferable and if there are any conditions or fees associated with the transfer process.

It’s important to note that the manufacturer typically provides warranties, not the contractor installing the coating system. However, reputable contractors will work with manufacturers who offer strong warranties and provide installation expertise to ensure the coating is applied correctly.

When evaluating warranty options, carefully read and understand the terms and conditions provided by the manufacturer. If you have any questions or concerns, contact the manufacturer or a knowledgeable roofing professional for clarification.

Remember that warranties are only as good as the manufacturer’s commitment to honoring them. Selecting a reputable manufacturer and following recommended maintenance practices will help ensure a positive warranty experience and the long-term performance of your roof coating system.

Pricing Considerations for Different Types of Roof Coatings

When considering roof coatings for your building, pricing is an important factor to evaluate. The cost of roof coatings can vary based on several factors, including the coating type, the roof’s size and complexity, the labor involved, and regional pricing variations. Here’s a breakdown of the pricing considerations for some common types of roof coatings:

Acrylic Coatings

Acrylic roof coatings are generally among the most cost-effective options. They are affordable and offer good durability and reflectivity. The pricing for acrylic coatings is often influenced by factors such as the product’s quality, the coating application’s thickness, and the roof substrate’s specific requirements. On average, acrylic coatings can range from $0.75 to $1.75 per square foot for materials and labor, depending on the roof size and condition.

Asphalt Emulsion Coatings

Asphalt emulsion coatings are known for their affordability and ease of use. They are typically priced competitively compared to other coating types. The cost of asphalt emulsion coatings depends on factors such as the product’s quality, the coating application’s thickness, and any additional materials required for surface preparation or reinforcement. Asphalt emulsion coatings can range from $0.75 to $1.50 per square foot for materials and labor.

Butyl Rubber Coatings

Butyl rubber coatings are often priced higher than acrylic and asphalt emulsion coatings due to their exceptional elongation and durability. The higher cost is primarily attributed to butyl rubber coatings’ superior performance characteristics and specialized properties. The cost of butyl rubber coatings can range from $1.50 to $3.00 per square foot for materials and labor, depending on the specific product and roof size.

Silicone Coatings

Silicone roof coatings are known for their excellent UV resistance and resistance to ponding water. They are often considered a premium option and are priced accordingly. Due to their unique characteristics and performance benefits, silicone coatings generally have a higher price point than acrylic, asphalt emulsion, and butyl rubber coatings. The cost of silicone coatings can range from $2.50 to $5.00 per square foot for materials and labor, depending on the product quality and roof size.

Urethane (Polyurethane) Coatings

Urethane coatings are highly durable and offer excellent adhesion and impact resistance. They are considered a premium coating option, and their pricing reflects the superior performance and specialized properties they provide. The cost of urethane coatings can range from $2.50 to $5.00 per square foot for materials and labor, depending on the specific product and roof size.

It’s important to note that these price ranges are approximate and can vary depending on geographic location, roof complexity, and specific project requirements. To get an accurate pricing estimate for your roof coating project, it’s recommended to consult with reputable roofing contractors or coating manufacturers. They can assess your specific needs, evaluate the condition of your roof, and provide you with a detailed cost estimate based on the chosen coating type and other project parameters.

Remember that while upfront costs are important, it’s equally essential to consider the long-term benefits and potential savings that a high-quality roof coating can offer. Investing in a durable and energy-efficient coating system can provide significant cost savings over the roof’s life through reduced energy consumption, extended roof life, and decreased maintenance needs.

How Long Do Roof Coatings Last?

The lifespan of roof coatings can vary depending on several factors, including the type of coating, the quality of the product, the application process, the roof substrate, and the environmental conditions the roof is exposed. While roof coatings can significantly extend a roof’s serviceable life, it’s important to note that the longevity of coatings can vary.

On average, roof coatings can last anywhere from 10 to 25 years. However, it’s crucial to remember that this estimate is a general range, and various factors can influence the actual lifespan. Some coatings may last even longer, while others may require recoating or maintenance sooner.

The specific type of coating can impact its longevity. Premium coatings like silicone and urethane are known for their durability and can provide longer service lives than other coating types. Acrylic and asphalt emulsion coatings can also offer reliable performance but may require more frequent maintenance or recoating.

Proper surface preparation, application techniques, and adherence to manufacturer guidelines are critical for maximizing the lifespan of roof coatings. Thoroughly cleaning the roof surface, repairing any damage, and ensuring proper adhesion during application can improve the coating’s longevity.

Additionally, the environmental conditions the roof is exposed to can impact the coating’s lifespan. Factors such as extreme temperatures, UV radiation, moisture levels, and air pollution can affect the coating’s performance over time. Regular inspections and maintenance can help identify and address any issues that may arise, allowing for timely recoating or repairs to extend the lifespan of the coating system.

It’s important to consult with reputable roofing professionals or coating manufacturers to assess your specific roof conditions and determine the expected lifespan of the coating system. They can guide the optimal coating type for your roof, considering factors such as climate, roof substrate, and budget. Following their recommendations and investing in high-quality coatings can help ensure the longest possible lifespan for your roof coating system.

Remember, proactive maintenance, periodic inspections, and timely recoating are key to preserving the coating’s performance and maximizing its lifespan. Regularly monitoring the condition of the coating and addressing any issues promptly can help maintain its protective properties and ensure its continued effectiveness in extending the life of your roof.

Important Physical Properties to Consider

Every commercial roof is different. That’s why it’s important to evaluate certain physical properties of a coating to ensure its suitability in a particular roofing environment. Each property listed below, as well as other technical data, can be found in the manufacturer’s product data sheets.

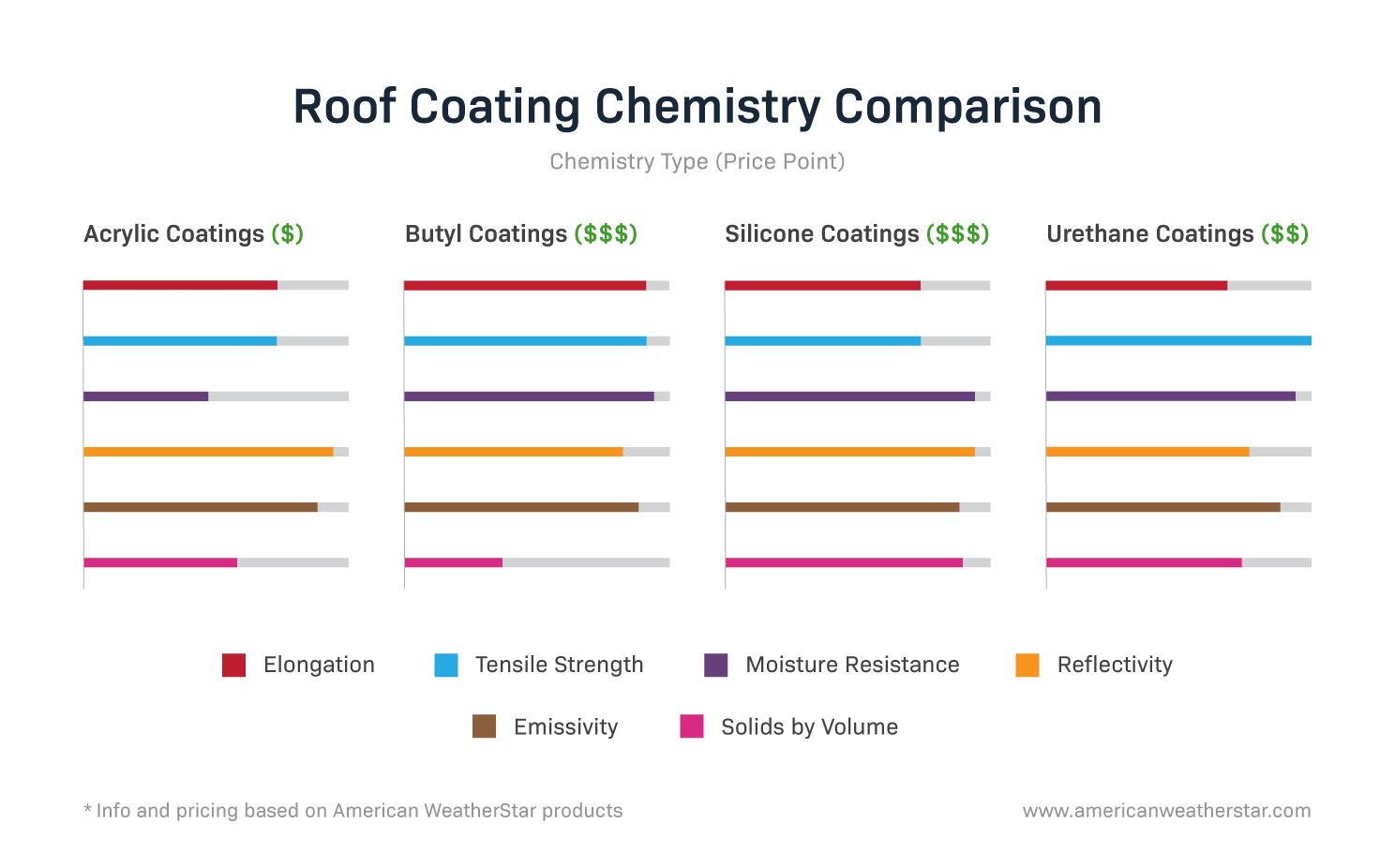

Elongation

Elongation is the percentage in which a material can be stretched before it breaks. Most elastomeric coatings typically measure anywhere between 250-900%. The higher the elongation value, the more suited a coating is to endure the normal expansion and contraction of a roof structure without cracking, thinning, or peeling off.

Tensile Strength

Tensile strength is the amount of pressure a material can withstand before it breaks. Depending on chemistry type, most elastomeric coatings rate anywhere from 250-1200 psi (pounds per square inch).

Elongation and tensile strength are closely related but in an inverse direction. As one increases, the other decreases. The best commercial roof coating formulas balance the two properties to provide a strong, durable membrane that can adequately stretch and move with roof surfaces.

Permeability (Moisture Resistance)

Permeability, or perm rating, is the state or quality of a material or membrane that causes it to allow liquids or gases to pass through it. This value varies greatly depending on the type of coating.

For example, acrylics have a high perm rating, meaning they are very breathable. Silicones, on the other hand, have a lower perm rating meaning they have superior resistance to moisture transmission. It’s important to note that higher permeability does not equate to inferior weather resistance.

Reflectivity

Reflectivity measures the amount in which a material can reflect light. It is typically represented as a percentage between 0-100%, with at least 85% being considered good reflectivity. Unlike conventional, dark-colored roofing materials, white roof coating systems reflect 80-90% of the sun’s energy back into the atmosphere—significantly reducing the risk of heat gain throughout the roof structure.

Emissivity

Emissivity refers to a material’s ability to release absorbed heat. This property is usually represented as a decimal between 0 and 1, with 0.65 being considered ideal for an elastomeric roof coating. This means 65% of the sun’s thermal energy is emitted away from the roof, thus reducing building heat loads and lowering cooling costs.

Solids by Volume

Solids by volume is the measure of how much solid material will remain after a substance has dried. Understanding this property is critical in order to properly achieve the required dry film thickness specified for certain coating systems. While it has no bearing on the performance of a coating, this particular property is certainly worth some consideration.

Though the physical properties highlighted above are the most notable in terms of performance, there are other data points to consider as well. For a complete overview of the physical properties for American WeatherStar products, click here to download our full roof coating comparison chart.

Conclusion

Ultimately, the performance of a commercial roof coating depends on a variety of factors. Each chemistry has its own unique set of strengths and weaknesses. Things like roof type, age, environmental concerns, aesthetics, and more must be taken into account before deciding on a suitable, long-term solution.

If you’re interested in one of our restoration systems, schedule a free roof inspection with an American WeatherStar Approved Contractor today.

Related Posts

5 Commercial Roof Maintenance Best Practices

Having a solid plan for commercial roof maintenance and repairs is critical to keeping your roof strong and preventing premature roof failure.…

5 Common Myths About Roof Coatings

Many maintenance and engineering managers have been misled about fluid-applied roof coating systems, and have developed a series of myths and…

What Are the Benefits of a Cool Roof?

Cool roofs are on the rise due to an increased recognition that cool roofs can help your building or home be more comfortable and…