Metal roof coatings provide many benefits. They do more than just stop leaks—they effectively reduce energy consumption, prevent rust and corrosion, lower maintenance costs, and extend roof life. More importantly, they are about half the cost of traditional roof tear-offs and replacements.

That said, when it comes to choosing the best metal roof coating for your building, there’s no shortage of suitable options out there. So how do you choose? It helps to understand the most common problems that typically occur on commercial and industrial metal roofs.

Common Problems Affecting Metal Roofs

Metal roofs present a number of challenges in regard to the performance of a coating system. For starters, metal roofs are notorious for leaking. While metal is a durable and long-lasting roofing solution, it’s not uncommon for leaks to occur as a result of compromised seams or loose fasteners. This is mostly due to the natural expansion and contraction (thermal movement) of the roof structure.

Corrosion and rust are also common occurrences on commercial metal roofs. While they are two separate things, both corrosion and rust (pictured below) are essentially chemical processes that result in the disintegration of materials. This is more of a long-term issue that causes roof panels to weaken—which inevitably leads to premature system failure.

PRO TIP: When coating a metal roof affected by rust or corrosion, the use of a rust-inhibitive primer is recommended to neutralize further deterioration of the metal material.

As metal roofs age, they tend to lose their reflective properties. As a result, they absorb more heat from the sun and become much less energy-efficient. This added heat can transfer to the building below causing an increase in internal building temperatures and a gradual spike in energy costs.

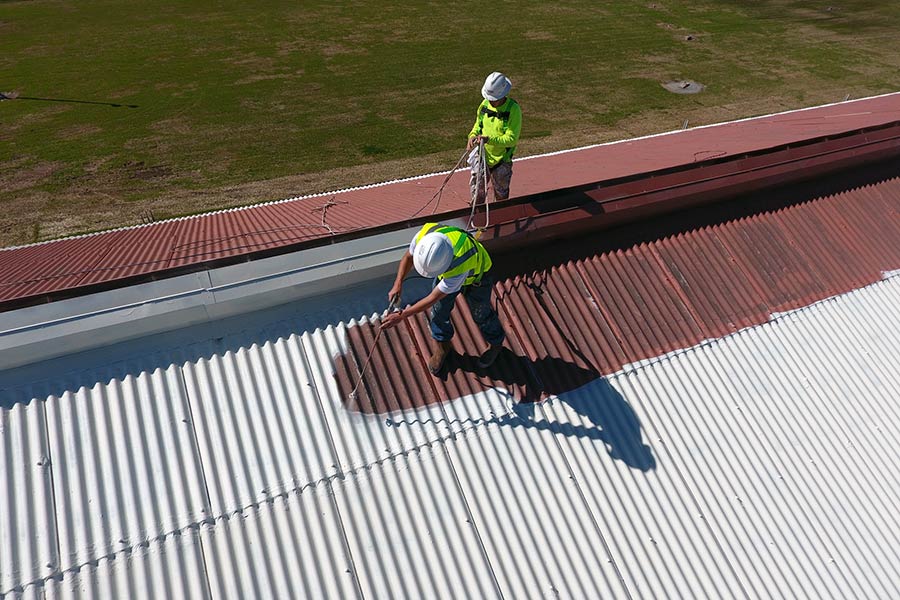

Fortunately, coating a metal roof is an effective and economical way to safeguard it from the elements. That said, it’s worth noting that not all metal roof coatings are created equal.

Metal Roof Coating Systems We Provide

At American WeatherStar, we manufacture a variety of highly-reflective ENERGY STAR® rated coatings specially formulated to restore, waterproof, and protect metal roof surfaces. Below, we highlight some of the key features and benefits of our best metal roof coating systems.

The Met-A-Gard Roof Restoration System

The Met-A-Gard System sets the standard for performance, durability, and affordability in metal roof restoration. This system is comprised of high-quality acrylic roof coatings developed with superior elongation, tensile strength, reflectivity, and mildew resistance.

The Met-A-Gard System is designed for maximum adhesion to metal roof surfaces. Its bright white finish creates a highly-reflective and energy-efficient membrane capable of enduring severe temperature variations and providing long-lasting UV protection and weatherability.

VIDEO: Click here to watch the Met-A-Gard System being installed on a low-slope metal roof.

The Met-A-Gard+ Roof Restoration System

The Met-A-Gard+ System offers many of the same benefits as Met-A-Gard, however, it utilizes a more advanced acrylic coating specifically formulated with greater elongation and tensile strength.

Like Met-A-Gard, this system adheres especially well to metal roof substrates and provides excellent UV stability, reflectivity, and elemental protection. Its industry-leading elongation and tensile strength make this system the preferred metal roof coating solution for extreme environmental conditions.

For those searching for a colored metal roof coating system, Met-A-Gard+ is developed with superior color retention, making it ideal for custom-tint roof coating applications. Click here to learn more about the many standard, premium, and custom color tints we provide.

The Met-A-Sil Roof Restoration System

If you’re looking for a silicone-based system for coating a metal roof, look no further that the Met-A-Sil System. It uses high-solids silicone roof coatings to provide the ultimate level of reflectivity, UV performance, and moisture protection.

The Met-A-Sil System is a great waterproofing solution for commercial and industrial metal roofs. Once cured, its high-performance silicone components form a seamless, flexible, rubber-like membrane that provides exceptional UV protection, reflectivity, and elemental protection.

The Color-Gard+ Architectural Roof Coating System

The Color-Gard+ System is our newest addition to the world of metal roof coatings. It combines advanced acrylic polymer and PVDC (polyvinylidene chloride) coatings to beautify and protect architectural metal roof applications. This system provides an aesthetic, flexible, high-gloss finish with superior abrasion resistance, colorfastness, and resistance to dirt pick-up.

Protecting Your Investment

For guaranteed protection and peace of mind, every fluid-applied roofing system mentioned above is eligible for long-term NDL System Warranties, which cover both material and labor of the installing contractor, as well as “material-only” warranty plans.

Click here to learn more about our StarGard Warranty Program.

Conclusion

As we have illustrated, metal roofs present a number of challenges when it comes to the performance of a coating system. The key to determining which metal roof coating performs best ultimately depends on its chemistry. As long as the system components can endure the negative effects of UV radiation and rust and corrosion, it is more likely to be successful in the long term.

If you are a facility manager or property owner and would like to know if metal roof coatings are right for your commercial facility, click here to schedule a free roof inspection with an American WeatherStar Approved Contractor.

Related Posts

The Pros and Cons of Acrylic Roof Coatings

Often referred to as the “original” elastomeric coating, acrylic roof coatings are generally a popular choice for sloped metal roofs. However,…

Met-A-Gard System on a Leaking Metal Roof

A large manufacturing company in the Atlanta area was having leaking issues in their metal roof for several years. In this scenario, an American…

What Are the Benefits of a Cool Roof?

Cool roofs are on the rise due to an increased recognition that cool roofs can help your building or home be more comfortable and…