It’s a question we get asked from time to time—which roof coating type is better, silicone or acrylic?

As a manufacturer of silicone and acrylic roof coatings, we know the advantages and disadvantages of each chemistry. Both materials provide numerous money and energy-saving benefits, and both can add years of serviceable life to aging commercial roofing membranes.

But in the case of silicone vs acrylic roof coating, choosing the most suitable chemistry depends on a variety of circumstances. Below, we give a brief overview of both silicone and acrylic roof coatings and discuss how they compare to one another in regard to:

- Cost

- Longevity

- Reflectivity

- UV Stability

- Durability

- Resistance to Ponding Water

- Application & Clean Up

- Environmental Factors

- Aesthetics

Side Note: For a more comprehensive overview of the various types of elastomeric coatings used in commercial roof restoration, click here.

Attention! Want to offer American WeatherStar roof coating systems and products to your customers? Click here to become an Approved Contractor today!

Silicone Roof Coating

Silicone coatings were introduced throughout the 1960s and ‘70s. They were used primarily in spray foam roofing applications but eventually evolved into a suitable coating solution for a variety of other commercial roofing substrates including metal, modified bitumen, built-up roofs, EPDM, TPO, PVC, and concrete.

Silicones are the most widely used coating material in modern commercial roof restoration. They are best known for their superior UV stability and resistance to ponding water. Silicones are a solvent-based material, meaning they are less susceptible to colder temperatures and therefore have a broader application window than water-based (acrylic) coatings.

Most of today’s silicone coating formulations have a solids content of 90% or greater, meaning less liquid material is used during application to achieve the required dry film thickness.

The primary drawbacks of silicone coatings are they can be challenging to spray, accumulate dirt, and are extremely slippery when wet. If foot traffic is expected on a silicone system, we highly recommend incorporating a walk path system to provide a slip-resistant surface.

Recommended reading: The Pros and Cons of Silicone Roof Coatings

Acrylic Roof Coating

Acrylic roof coatings have been around since the 1950s and remain a popular choice in the commercial roof restoration industry. They are suitable for use on a variety of substrates including metal, modified bitumen, built-up roofs, EPDM, TPO, PVC, concrete, and spray polyurethane foam.

Acrylic coatings are best known for being cost-effective, UV resistant, environmentally friendly, and easy to work with. Unlike silicones, acrylics are easy to clean up and are less harsh on application equipment.

Although acrylics are suitable for use on a variety of substrates, we highly recommend they only be used on steep-slope metal roofs where ponding water is not an issue. As a water-based material, acrylics do not hold up well to standing water.

Recommended reading: The Negatives of Acrylic Coatings on Flat Roofs

Acrylic systems are prone to losing mil thickness as they age. They are also susceptible to freezing at colder temperatures. Acrylics need to be installed when outside temperatures are at 50°F or higher to achieve optimal adhesion.

Recommended reading: The Pros and Cons of Acrylic Roof Coatings

Silicone vs Acrylic: How They Compare

Now that we’ve covered the basics of silicone and acrylic coatings, let’s see how the two chemistries stack up to one another in this silicone vs acrylic roof coating comparison.

Cost

Acrylic coatings generally cost less than silicones. While acrylics do have plenty of other notable qualities, their price point is the great equalizer in the silicone vs acrylic roof coating debate.

Longevity

Many factors can affect the longevity of an elastomeric coating, but mil for mil, silicones last longer than acrylics. This is mostly due to the inherently superior UV and moisture resistance of silicone materials.

Reflectivity

Both acrylic and silicone roof coatings have a thermal reflectance between 80-90%, meaning both chemistries perform similarly in terms of reflectivity—at least in the short term.

Silicone-coated roofs tend to get dirty within 6 to 12 months after application. While this trait isn’t necessarily a detriment to performance, it can lead to a slight loss in reflectivity over time. For this reason, we give acrylics the edge when it comes to thermal reflectivity.

UV Stability

Silicone roof coatings are far superior to acrylics in terms of UV performance. Unlike acrylics, silicones do not chalk, break down, or become brittle from prolonged exposure to the sun’s harsh ultraviolet rays.

Durability

Although they possess similar tensile strength, silicones are more durable than acrylics in the long run. Acrylic coatings simply don’t have the staying power of silicones. In fact, acrylic coating systems are known to lose mil thickness as they age.

Resistance to Ponding Water

Silicone coatings are best known for their resistance to ponding water (water that remains on the roof surface for more than 48 hours). This makes silicone the go-to solution for commercial flat roofs where ponding is more likely to occur.

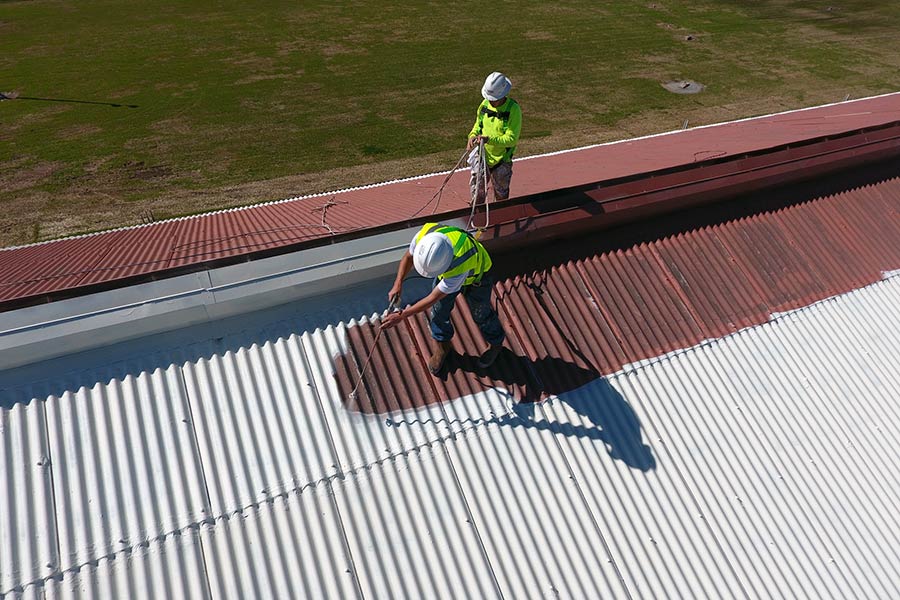

As previously mentioned, acrylic materials will break down rapidly (pictured above) if subjected to long bouts of ponding water.

Application & Clean Up

Compared to silicones, acrylic coatings are much easier to install. They are far less problematic on application equipment and only require water for clean-up.

Silicone coatings, on the other hand, can be quite difficult on application equipment and require virgin mineral spirits for clean-up.

Environmental Factors

As a water-based material, acrylic coatings are naturally the safer choice when it comes to the environment.

That said, many of today’s silicone coatings are formulated with little to no solvents and have extremely low VOCs (volatile organic compounds). This means certain high-solids silicone coatings are also considered environmentally friendly.

Aesthetics

Although they are similar in appearance, acrylic coatings are more aesthetically pleasing than silicones in the long run. Acrylics are the best choice for steep-slope architectural metal roofs that are visible from the ground or nearby buildings.

As previously mentioned, silicone coatings have a tendency to accumulate dirt over time. While this issue has minimal impact on longevity and performance, it can cause silicone-coated roofs to become rather unsightly.

Both acrylic and silicone coatings can be tinted to custom colors, but unlike silicones, certain acrylic coatings are specifically formulated to hold their color longer.

Which Is Better, Silicone or Acrylic?

In the case of silicone vs acrylic roof coating—who comes out on top?

Pound for pound, silicones are the best type of roof coating material on the market today. Their superior waterproofing and UV stability simply cannot be matched by other coating materials.

While silicone coatings are superior to acrylics in a lot of ways, it doesn’t mean they are the most appropriate solution for every roof restoration project. As we have said ad nauseum, choosing the proper roof coating solution depends on a number of critical factors.

Below, we recap when it is best to use acrylic and silicone coatings.

When to Use Acrylic Coating:

- A building has a steep-slope metal roof

- Application can be done at temperatures above 50°F

- Prolonged aesthetic appearance is a priority

- Building owners and/or contractors desire easier application

- Environmental concerns must be taken into consideration

- Material cost is a concern

When to Use Silicone Coating:

- A building has a flat roof with ponding water issues

- Waterproofing is paramount

- Applications in colder temperatures

- UV stability, durability, and longevity are a priority

- Roof aesthetics are not an issue

Still not sure which type of coating to go with for your commercial roof?

Click here to schedule your free onsite roof evaluation with an American WeatherStar Approved Contractor. Our Approved Contractors will thoroughly survey your roof and accurately determine the best coating choice for your roofing needs.

Related Posts

Roof Mastic—What Purpose Does It Serve?

Roof mastics (also known as roof repair mastic, roof mastic sealant, or roof mastic coating) are used to seal any areas of a commercial or…

Storing & Working with Moisture-Cure Coatings

While there are many benefits to moisture-cure coatings, it is critical to have a basic understanding of best practices for storing and working…

The Pros and Cons of Acrylic Roof Coatings

Often referred to as the “original” elastomeric coating, acrylic roof coatings are generally a popular choice for sloped metal roofs. However,…